Tyre Valve inspection and structure requirements, roles and types

The role of the tyre valve is to act as an inflate interface and deflate valve, and to keep the charged air from leaking out; it is also a device for checking the tyre pressure. Valves can be divided into two types: one is metal, the main body is brass; one is rubber pad, the main body is rubber metal. The valve body is equipped with a valve core that works like a one-way valve, and compressed air can be filled into the inner tube without being free to leak. The valve cap can also be used as a wrench to screw in and out the valve core. There are bridge pads and compression nuts on the metal valve to improve the tightness of the inner tube.

There is a bridge pad and a compression nut on the valve to improve the tightness of the inner tube.

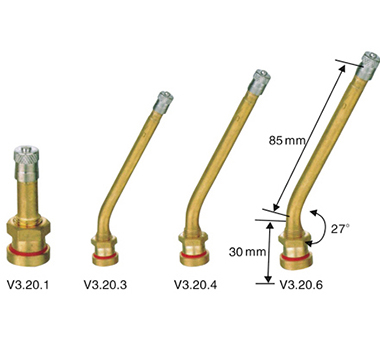

The shape of the valve is two types: elbow and propeller. The elbow valve is only used on flat rims. When the rear wheels are twins, the use of the elbow valve can inflate the inner file without removing the outer tire.

Valve inspection requirements:

(1) The surface of the tire valve body should be smooth, free of burrs, cracks, oil stains and rust; the area of the vulcanized rubber pad must not have rough surfaces.

(2) The difference between the long and short axis of the ellipsoid of the mouth bend is not more than 1.8mm.

(3) The gasket surface should be galvanized or other plating.

(4) Nuts and protective caps (Type B) shall be deoiled and derusted.

(5) TZl-type tire valves should be able to seal 1.5MPa (15k9 person m2) air pressure, TZ2 and other models should be able to seal 1.oMPa (10kg/cm') air pressure.

(6) The tire valve is equipped with a standard tire valve core, and the specified air pressure is passed into the water, and no bubbles must escape within 2 minutes.

(7) The rim valve should meet the requirements of this standard. It is manufactured in accordance with the approved drawings and documents.

(8) Tire valves shall be factory tested by the manufacturer. Each batch of products shall meet the requirements of this standard and be accompanied by a product quality certificate.

Valve structure requirements

(1) Easy to inflate and deflate;

(2) The internal pressure in the inner tube can be checked;

(3) Air tightness (no leakage of air in valve);

(4) It can be firmly combined with the inner wall, but it can also be replaced;

(5) Valves of various types and specifications are simple in construction, and each part has a uniform specification for replacement;

(6) Steady working pressure of the inner tube;

(7) Lightweight