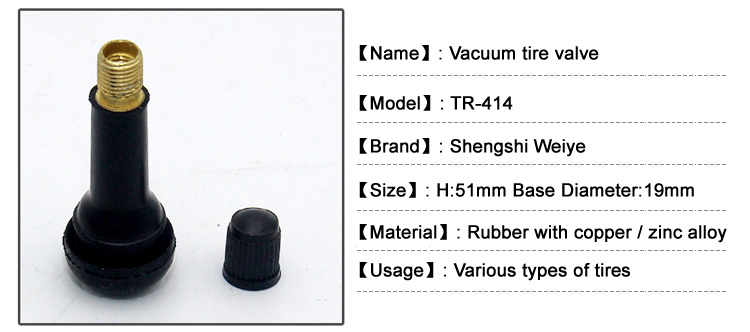

Vacuum tires Tire Valves TR414

1) Model No.: TR414,

2) 100% leak detection,conform to European standard

3) Cold, Heat and Ozone Resistant

4) Materials available: natural rubber and EPDM rubber

5)Each item must be approved by 100% leaking

| YX NO. | Stem Material | Outside Material | Metal Stem Height | Total Height | Screw Thread | Inside Screw | RIM HOLE | |

| TR-414 | Zinc Alloy,Brass | Natural Rubber | 37.2mm | 49mm | 8v1 | 5v1 | 11.5mm | |

| Weight | 0.8g/valve core,0.3g/cap,abt9.5g/piece | |||||||

| Pcs/Carton | 100pcs/bag,10 bags/carton | |||||||

| Carton Size | 38x30x13cm | |||||||

| Q'ty/20'FCL | about 1500 cartons | Q'ty/40'FCL | about 3500 cartons | |||||

1.Our tubeless tire valves tr414 are leak tested.

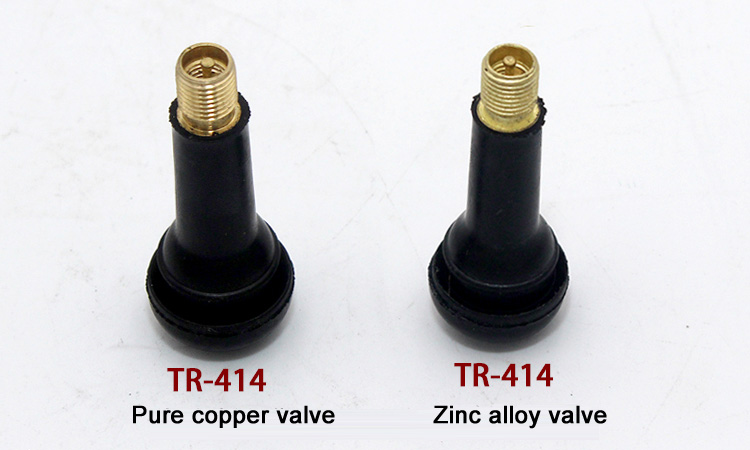

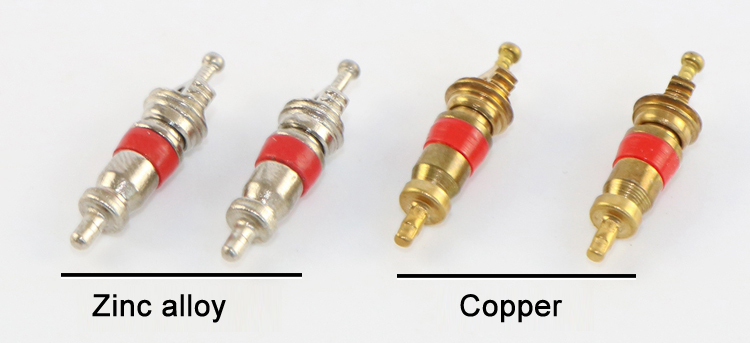

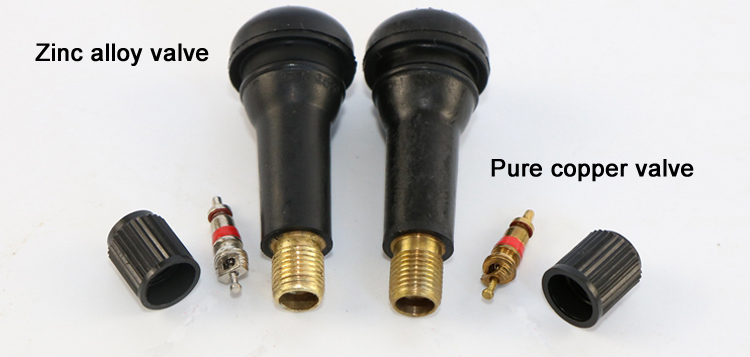

2. Our main products Zn alloy with 10%brassTR414,about9.4g per piece.Brass TR414 should with more than 55% brass,can't more light than zinc alloy.

3.We specialize in tire valves field for 20 years, with the strength of TR414.

4.Our TR414 tire valve is very popular in market of Southeast Asia,Eastern Europe,South America,Middle East,Africa for many years.You can rest assured purchase.

- Packaging Details

Pro Tip: As a leading tire valve manufacturer, Shengshiweiye recommends EPDM valves for all-season driving.

Tire Valve FAQ

Q: What is the difference between TR413 and TR414 tire valves?

A: The primary difference is the length. The TR413 has an effective length of 30mm, while the TR414 is longer at 38mm. Both are designed for a standard 11.5mm (.453") rim hole and support up to 65 PSI cold inflation pressure. Choose TR414 for deeper rims or easier access.

Q: Can I use rubber snap-in valves for high-pressure truck tires?

A: Standard rubber snap-in valves (like TR413) are rated up to 65 PSI. For truck or commercial tires requiring higher pressure, you must use High-Pressure Snap-in Valves (rated up to 80-100 PSI) or Metal Clamp-in Valves (rated up to 200 PSI) to prevent stem failure Category.

Q: Why is EPDM rubber better for tire valve stems?

A: EPDM rubber offers superior resistance to heat, ozone, and weather aging compared to natural rubber. It prevents premature cracking and air leaks, especially in extreme temperatures (-40°C to +100°C), ensuring a longer lifespan and higher safety for tubeless tires.

Q: How often should tire valve stems be replaced?

A: You should replace tire valve stems every time you install new tires. Rubber degrades over time due to heat and road chemicals. Reusing old valves increases the risk of slow leaks or sudden air loss, even if the new tire is in perfect condition.

Related Reading:

Are Tire Valve Caps Universal? A Complete Guide for Car Owners

Next: Shengshiweiye Tubeless Tr413 Tire Valve For Auto Parts

Leave a Reply